K - Aluminum-coated module for hot water (ondol)

K - SPC flooring finishing material for hot water (ondol)

| Module Size (L*W*H) mm | 600 X 1,200 X 30 |

|---|---|

| Compressive Strength (kPa) | 350 |

| Water Absorption Rate (v/v) | 1% |

| Thermal Conductivity (mK) | 0.03 |

| Fire Rating | B1 |

| Heat Source | Compatible with existing boilers & electric water boilers |

| Weight per Module (Kg) | 0.8 Kg |

| Product Features | Attached aluminum on top for a temperature increase of 5.8℃. The substrate has low thermal conductivity (0.03 w/mk) for maximum energy savings. |

K - Aluminum-coated module for electric (heating cable)

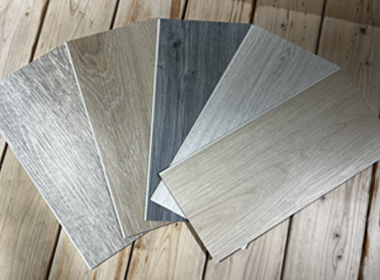

K - SPC flooring finishing material for hot water (ondol)

| Module Size (L*W*H) mm | 600 X 1,200 X 20 |

|---|---|

| Compressive Strength (kPa) | 350 |

| Water Absorption Rate (v/v) | 1% |

| Thermal Conductivity (mK) | 0.03 |

| Fire Rating | B1 |

| Heat Source | Standard electricity | 1 pyong | 25 w/m | 550 w |

| Weight per Module (Kg) | 0.6 Kg |

| Product Features | Attached aluminum on top for a temperature increase of 5.8℃. The substrate has low thermal conductivity (0.03 w/mk) for maximum energy savings. |

| K-Aluminum Coated Module | T1 | Above heating wire | 47.1 | ℃ | Temperature Difference | 4.8℃ higher |

|---|---|---|---|---|---|---|

| T2 | Between heating wires | 35.5 | ℃ | 6.8℃ higher | ||

| General Module | T3 | Above heating wire | 42.3 | ℃ | - | |

| T4 | Between heating wires | 28.7 | ℃ | - | ||

| Experimental Results | The aluminum-coated module has an average temperature 5.8℃ higher than the general module, allowing for even heat distribution. | |||||

K - Module for hot water, thickness 30mm

K - Module for electricity (heating cable), thickness 20mm

K - SPC flooring (reference material)

K - Hot water pipe, 16mm

K - Heating cable (reference material)

K - Electric water boiler, 3 ~ 5Kw

K - Hot water pipe, 12mm

K - Electric heating thermostat

K - Carbon electric heater, 3 ~ 5 pyeong

K Nanbang Technology Co., LtdCEO : Park Sang-gun

Tel(Q&A) : 010-3609-8967 TEL : 041-592-8877FAX : 041-592-5588E-mail: knanbang600@naver.com

ADD : 58-82, Namsan 3-gil, Seonggeo-eup, Seobuk-gu, Cheonan-si, Chungcheongnam-doBusiness registration number : 377-87-02137

Copyright ⓒK-HEATING TECHNOLOGY CO.,Ltd. All Rights Reserved.